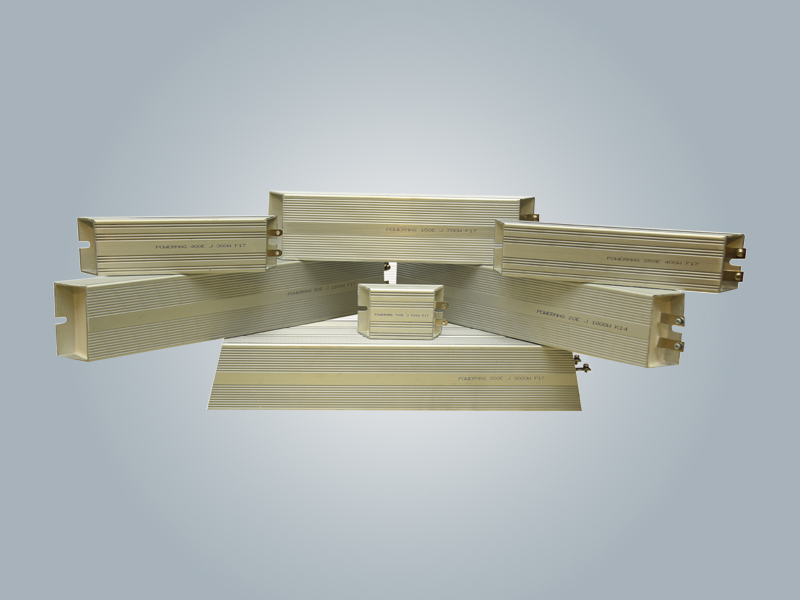

Aluminum housing Dynamic Braking Resistors (DBR)

- POWERMAG Aluminium housing dynamic braking resistors (DBR) are based on a high grade FeCrAl Alloy wire wound on threaded ceramic formers

- The resistance material is a high grade FeCrAl Alloy

Rated for repetitive duty

- Robust & Noise Free construction

- High overload capacity

- Close tolerance (+/- 5%)

- Temperature stable element

General Features

- These elements have a high overload capacity and cool rapidly

- Compact construction & Low Noise Level

- Higher continuous dissipation by mounting directly onto heat sink or cooling surface

Specifications

- Terminals: Nickel Copper Plated M.S. Terminals or 300-500mm long Temperature Resistance Cable

- Mounting Positions : Any mounting position is possible at full load, but recommended positions are as follows

- Installation: The resistors do not have a separate safety earth terminal. They must be mounted on a metallic bare, grounded surface or an earth terminal must be affixed to one of the fastening screws

- Safety: For unprotected installation within normal arm’s reach, use a protection against unintended contact

- Sufficient cooling air must be available and sufficient headroom above the unit for the exiting hot air.

| Technical Specifications | |

|---|---|

| Operating Temperature | -55°C to +375°C for 1 min |

| Operating Voltage | 600VAC 1100VDC (850VDC) / 690VAC |

| Insulation Resistance | > 100 MΩ at 500V |

| Dielectric Strength | No breakdown at 2.5 kVAC RMS |

| Short Time Over Load | 2 x Wattage Rating, 10 sec |

| Resistance Tolerance | ± 10% (standard) or ± 5% (optional) |

| Core Material | Ceramic |

| Coating on Core | Silicon Epoxy Resin |

| Terminals | Nickel Copper Plated MS Terminals or Temperature Resistant Teflon Cables |

| Resistor Element | High Grade FeCrAl Alloy |

| Maximum Temperature | 375°C at full load above an ambient temperature of 40°C |

| Housing | Anodized Aluminium |

| Cooling | Air Natural |

| Standards | IEC 60068-1 & IEC 61180-1 / CE Marked |