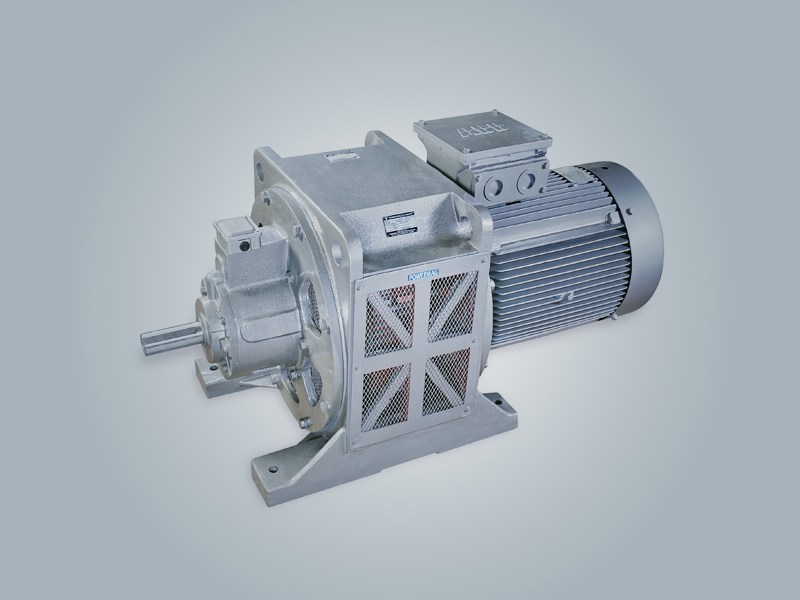

“POWERMAG” consists of a totally enclosed, fan cooled (TEFC), flange type three-phase squirrel cage induction motor is mounted on to an eddy current clutch, having a projected, self-ventilated common frame design. There is no physical contact between motor and clutch. This results in smooth response, there by eliminating shock loading and extending equipment life.

“POWERMAG” eddy current variable speed drive operates on AC power supply and provides constant torque at variable speeds over a wide range. “POWERMAG” eddy current variable speed drives are economical and widely used for various Industrial applications.

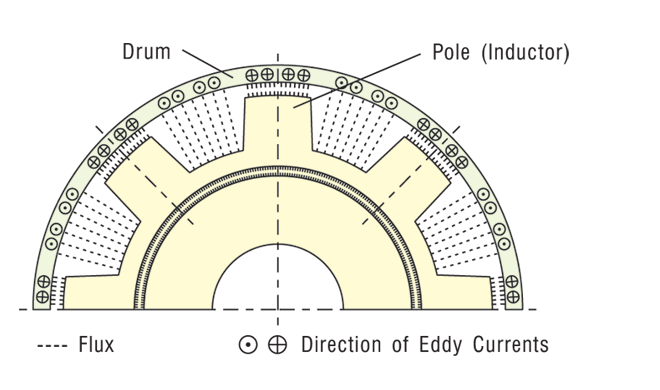

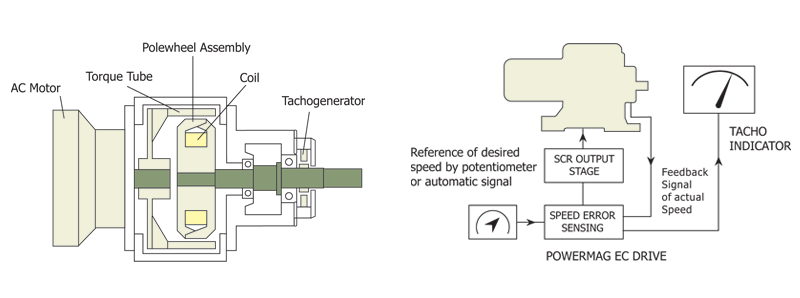

The primary elements of POWERMAG eddy current variable speed drive are an AC motor, an eddy current clutch, a tacho generator and a seperate small solid-state electronic controller. The eddy current clutch consists of two rotating members : a drum driven at constant speed by the AC motor and within the drum, a rotor / output shaft which connected to the load. Torque is transmitted from the drum to the rotor / shaft through an adjustable magnetic field that attracts the two members. The magnetic field is produced by a clutch coil typically below 2% of the total drive power requirements which means smaller and longer – life controller circuits can be used.

All POWERMAG eddy current variable speed drives have an integral tacho generator mounted around the output shaft, to give voltage and frequency proportional to speed, which is used for speed reference feed back signal to the controller and maintains the output speed within 2% for the load changes from 90% to 10%. It can also be used for speed indication.